PE foam (Polyethylene) can be found everywhere in our lives, but do you know the performance and recycling solution introduction of PE foam material?

Characteristics of PE foam

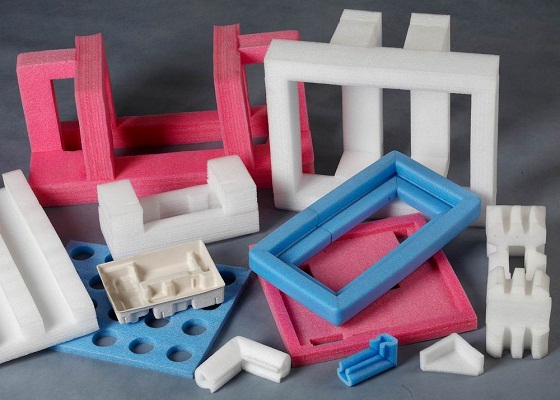

PE foam is an advanced protective inner packaging material. It has high growth hormone elasticity and white appearance. Because it is a completely independent bubble, it is lightweight and flexible, and can be bent to absorb the impact dispersion and cushioning effect, and overcome the fragility, deformation, and recovery failure of ordinary EPS foam.

PE foam has resistances such as heat preservation, waterproof and moisture proof, heat insulation, sound insulation, anti-friction, anti-aging, corrosion resistance, anti-aging ability. At the same time, the PE foam material with antistatic agent will have significant anti-static properties.

It is an ideal substitute for traditional packaging materials. PE foam has been widely used in product packaging, such as computers, electrical appliances, high-end furniture, leather goods, handbags, shoes, etc. Especially the packaging of high-end crafts. PE foam will be the development trend of packaging.

Use range of PE foam material

PE foam is widely used in electronic appliances, instrumentation, computers, medical equipment, lighting, handicrafts, ceramics, home appliances and gift packaging. After adding antistatic agent and flame retardant, it will show its excellent performance remarkably.

It is also widely used in elastic lining bags, pads for breeding and heat preservation, heat insulation materials, heat preservation materials, mobile equipment agricultural industrialization, sports goods, water rescue equipment operations, home, hotel floor decoration, packaging, etc.

Adhesive products of PE foam and various fabrics can be used as additive materials for vehicles, bedroom decoration. At the same time, they are good materials for cold storage.

PE foam recycling solution

PE foam is always considered difficult to recycle due to its high elasticity. GREENMAX PE foam densifier uses a larger motor to crush the PE foam and cut it into small pieces, and then extrude to the molding head, the extruding head has a heater to heat the surface of the PE material into dense blocks, and then you will get surface melted foam blocks.

GREENMAX ZEUS Series foam recycling machine is specially designed for waste PE foam recycling, the whole process is safe and efficient, thus making PE foam recycling more effective than before.