The production of plastic foam is based on petroleum and has a strong durability, so such materials as EPS foam have been regarded as a major threat to the environment.

As a surge in COVID-19 has shut down indoor dining in two dozen Colorado counties, restaurants are once again turning to pickup and delivery orders as the lifeblood of their business. However, this means that there will be a large number of food packaging boxes produced, of which the highest proportion is EPS foam.

“More takeout orders will have a bad impact on our environment,” said Danny Katz, director of the Colorado Public Interest Research Group. “We can contaminate the world for hundreds of years without taking food with us for a few minutes at a time.”

Yes, EPS foam waste is not easy to decompose, once it is discarded in the natural environment, it can exist for hundreds or thousands of years. Especially in many areas, landfill is still the main method of EPS foam disposal. In fact, we do not support this processing method, EPS foam recycling can not only avoid the pollution to the environment, but also realize the recycling of resources.

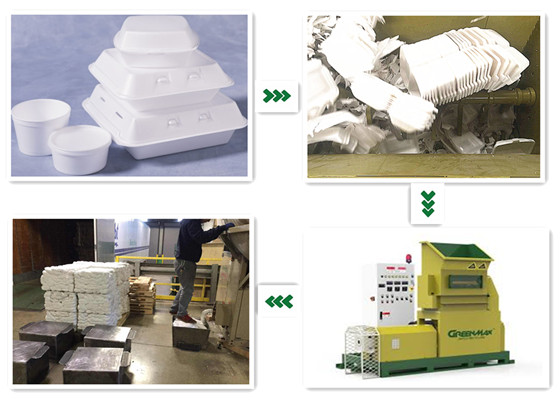

GREENMAX foam recycling machine is a good tool for waste EPS foam recycling. The foam compactor adopts the screw compacting technology to do foam recycling by crushing and compressing, the main advantage of this equipment is environmental protection and no pollution. GREENMAX also offers professional foam densifier, the hot melt machine. With screw melting technology, the equipment can reach 90:1 foam volume reduce ratio. Both of these machines are of high quality and easy to operate, so you can choose according to your needs.

The problem of EPS foam is not unsolvable. The key is the application of foam recycling machines and the policy of the local government. Recycling is the most ideal solution for foam waste disposal at present.