Styrofoam compactor used to process waste styrofoam

are very common in our lives, and usually accompany our lives, but this kind of

machinery and equipment should also pay attention to some related matters

during operation. For example, the blade on the crusher of a cold press may

need to be replaced in time after it has been used for a period of time. How to

replace it?

There is a screw hole specially used for

fixing on the blade seat. We can use the corresponding wrench to remove the

blade and replace it immediately, but we need to wear gloves to avoid scratches

when replacing it. The correct blade gap is generally controlled between

0.15~0.25mm. Note that we must make adjustments in time. Avoid using blades

with too dull blades to avoid aggravating the wear of the cold press in the

later use. Before the cold press is officially started, we can turn the rotor

first, mainly to check whether the claws, hammers and the rotor are running

flexibly, whether there is any collision in the shell, and whether the rotation

direction of the rotor is in line with the arrow. It means that the direction

is the same, whether the cold press is lubricated well, these need to be

checked in advance.

If the inspection is not done in time

before the operation, the blades of the cold press will be excessively worn,

which will directly cause the blades of the cold press to not perform their due

performance, especially the blades of the cold press crusher have high working

strength. The loss is more obvious. Once the excessive wear of parts occurs,

the production capacity will be affected. Therefore, once we find that the

blades are excessively worn during the use of the cold press, we need to

replace the blades in time; in this way, the machine can run stably for a long

time without causing any damage to the machine. The loss.

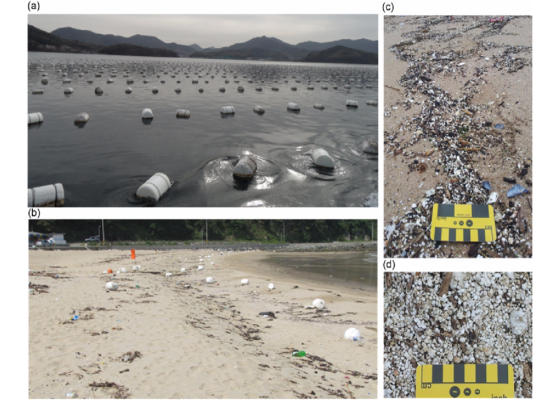

At present, the styrofoam compactor is a very common styrofoam

recycling equipment. If the waste styrofoam is not recycled in time, it will

pose a serious threat to the ecological environment around us. Therefore,

according to the needs of the society, the cold press The emergence of a timely

solution to some of the threats to the environment from waste styrofoam.

For some ocean styrofoamy garbage, it may

be more difficult to treat than ordinary styrofoamy garbage, but we can treat

the garbage before it enters the ocean. Choosing the right time to use the styrofoam compactor to recycle it

will not only protect the marine life but also our environment.

Nowadays, the scale of waste styrofoam

recycling is also gradually developing, thanks to this styrofoam compactor

recycling machine. Compressing the waste styrofoam after coming out is

convenient for later storage and transportation, styrofoam granulation, that

is, styrofoam modification and regeneration, which not only improves the

environment but also saves resources.