The Great Lakes receive more than 22 million pounds of plastic waste annually. In Michigan, only 14.25 percent of recyclables were actually recycled in 2019. By focusing on environmental projects and education, Michigan increased this percentage to 19.3% in 2022. In some areas, hard plastics marked with recycling symbols 1-5 and 7 can be washed and thrown into the recycling bin, but plastic foam marked with the number 6 must be placed in a designated location for recycling. White pollution.

The waste we talked about with the number 6 printed on it is PS foam. The PS that is often used as packaging is usually in an expanded state, regardless of the size of the shape. Some are large pieces of packaging, and some are like small pieces of EPS peanut packaging. , and even some in the form of EPS beads. No matter what form it is, as long as it is waste of EPS material, it needs to be recycled. Our recycling activities should not be limited to a certain area. We should continue to expand the recycling of EPS, and even combine EPS activities in multiple regions to form a large-scale recycling activity, so that the waste can be processed in a centralized manner. Not only is it more efficient, but it will also have greater publicity and educational significance.

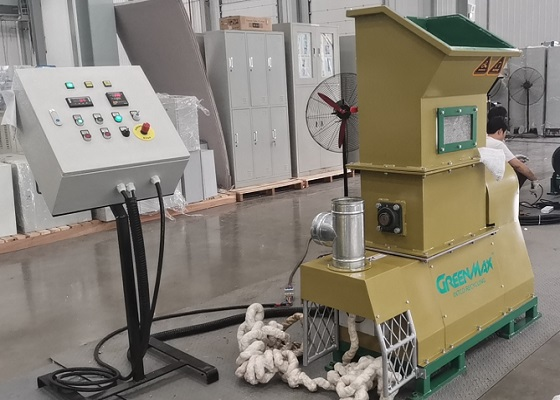

Installing an EPS hot melting machine at the site of recycling activities can process EPS in a timely manner. From crushing to heating and melting to extrusion, the volume of EPS can be compressed to 90% of the original volume in just a few very simple steps one, after compression, these hot melts will become very hard after cooling, and can be sold to make plastic particles and realize recycling. These plastic particles can be manufactured into new plastic products to achieve a real EPS recycling system. These plastic particles are usually manufactured into items such as photo frames, mirror frames, hangers and flower pots.