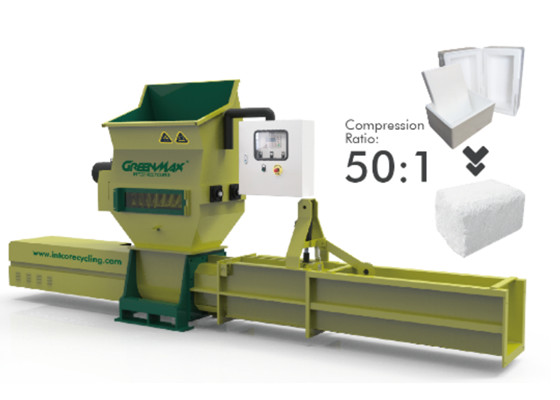

Among kinds of Styrofoam recycling machines, almost the Styrofoam compactors and Styrofoam hot melting densifiers account the most of the Styrofoam recycling market. Compared to the hot melting machines, the Styrofoam compactor does not need to be heated but the operation needs strict technology. It is easy to have various failures if treated causally.

Today we have the honor to find the GREENMAX after-sales specialists of Styrofoam recycling machine to learn how to deal with the recovery of a Styrofoam compactor when some common failures occur, including the control system and the hydraulic system.

Failure Recovery of Styrofoam Compactor for Control System

The most common failure occurs is the out-of-order of the hydraulic. The causes the specialists point out include that the window of crusher is open, or forget to press the RESET button when turning the machine on, or the wire connecting the hydraulic system is loose. Recovery solutions is first to close the window, and press the RESET button then check the wire and tight it.

When the crusher or screw is out of order, both may because the crusher window is open, the reason for crusher lies that debris are mixed in, causing the machine stuck and unable to operate, or the wire connecting the crusher motor is loose. Under these circumstances, you should check the crusher and clean the debris and also check the wire and tight it.

Failure Recovery of Styrofoam Compactor for Hydraulic System

The Hydraulic system is the biggest feature of this Styrofoam recycling machine, and also the most important part of the Styrofoam compactor. Let’s see what failures will happen and the recovery solutions.

People who are not familiar with this Styrofoam compactor may often find the Jaws do not move. Do not worry, we list all of the causes below:

- Low pressure

2. Wrong rotary direction of E-motor

3. Malfunction of Electromagnetism valve

4. The wire connecting motor or valve is loose.

The recovery solutions include to regulate valve; to adjust three-phase wire; to push valve core several times or replace it; to check the wire and tight it again.

Do you know how to dispose the leaking problem? We should first grasp the causes to know if it is because valve leakage, or tube leakage, or cylinder leakage, or valve leakage. The recoveries include to check the O-ring of the Valve and replace it, to replace it and to replace O-ring and check the connection of tube and cylinder.