If it is not for recycling, countless waste foam can only be piled up on the smelly landfill day by day. People can hardly imagine how long they need to finish their self-degradation. Those waste not only pollute the air we breathe everyday, the water we drink, it also cause much damage to the land and the wildlife around.

According to some scientists, those foam waste can stay on the landfill up to 200 to 400 years without manual processing, and some even 500 years. People may feel inconceivable or even ignore that such disposable plate or cup they use for one or five minutes could even cause a permanent pollution. Hence, it can not be denied that recycling is not only crucial but also inevitable.

Usually, the recycler condenses the recyclable material into bundles and then sells them by weight, of which the foam used is almost air, occupied 98%, which makes the transportation very expensive. Therefore, how to make recycling more convenient and how to cut back the transportation costs seem to be quite important and now we know that the first step of foam recycling is to reduce the bulky volume.

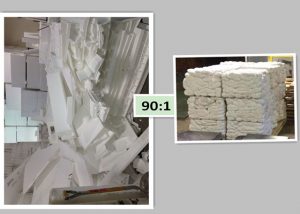

Styrofoam densifier supplied by GREENMAX is an American brand machine, with its assemble and install factory in China. The densifier is a machine that can smash the bulky foam into pieces and then melt the pieces into small volume ingots at a ratio of 90:1. It means that the densified ingots can be 90 times smaller than the loose Styrofoam.

Such good machine is really a good option that you can choose for applying in your Styrofoam recycling process and if you want to join in Styrofoam recycling, welcome to know more about GREENMAX.