With the holidays approaching, family and friends exchange gifts. Whether you are shopping in a mall or online, products generally have EPS packaging, and these EPS packaging are mainly responsible for freshness preservation, heat preservation, and impact resistance. At present, EPS is also one of the most popular packaging materials for merchants. These EPS are usually thrown into the trash can after the festival, and some people even mix them into other types of garbage, which makes the subsequent garbage sorting and recycling process extremely difficult, and throwing EPS indiscriminately will even cause other wastes. This type of waste cannot be recycled and ends up in landfills along with EPS.

Therefore, ensuring that EPS is correctly sorted and recycled is also responsible for the recycling of other types of garbage. Because EPS has been broken and light in weight, due to the effect of static electricity, EPS is easily broken into beads, and then adsorbed on other waste. So how to deal with EPS waste should draw our attention.

Classification of EPS waste

Residents can collect EPS waste in bags and put it in a designated place. Do not mix EPS with other types of waste. They can classify from the perspectives of whether watse can be recycled or degraded. The specific situation can be operated according to the local classification rules.

Recycling of EPS

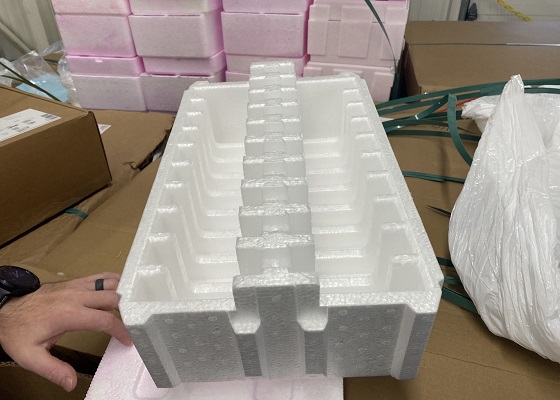

In order to carry out effective EPS recycling, many areas are gradually increasing the recycling sites that can accept EPS waste. It can be seen that people are determined to recycle EPS. But recycling can’t just rely on enthusiasm, so you should choose the correct recycling method. Utilizing EPS compactor is a good choice. The most difficult part in recycling EPS is transportation and waste management. All this is because 98% of the EPS body is air, so the air inside must be squeezed out first, so that it can be recycled more efficiently. The EPS compactor is used to break the waste into small pieces for compression. Such EPS blocs are not only smaller in size, but also not as easy to break into beads as before, and it is also more convenient for waste management.

The EPS compressed by the EPS compactor can be sold. At present, EPS blocs are raw materials in short supply, and people have begun to accept mixing recycled materials with new materials to make new plastic products. Therefore, with the increase in the supply of raw materials, more and more people have found business opportunities and began to actively consult Intco Recycling GREENMAX EPS compactor, wanting to carry out recycling projects. If you also have this idea, please feel free to contact us!